Mechanical Reduction Gear Set

I successfully completed a 4 months school project (56 hours expected) at the Graduate School of Mechanical and Industrial Engineering (Arts et Métiers, ENSAM), consisting of conceiving from scratch a reduction gearbox. I did this work with a teammate named MIRI Ilyès.

If you want to understand all choices we made in order to fulfill this conception, you can read the following report or look at the support of the oral presentation associated.

Objectives

We had to conceive a box which admits 2 circular axles linked together by a relation on their rotation speed. All the formulas were explained in our lessons. So our work focus on how to choose each shape and each dimension of the assembly in order to have :

- a system economical

- a system mountable and unmountable

- a system resistant to load of flexion and torsion on the entry axle

- a system achievable with basic machining machine

- a system oil-tight

Conception

Every constraint includes another one. For example, in order to have a system resistant to flexion, it imposes a minimum axle diameter, which impact the size of the seals, which impact the cost of the system. All of those constraints makes the work really interesting, it’s important to respect every specification in order to have a functional system. We inspired a lot from existing system, then we tried to simplify every shape, in order to win time in the building process. We imagined all the building process, we thought about simplifying this process for an eventual assembly-line worker. We decided to make an almost symetrical case made out of two similar parts. We tried to put in place rounded size to simplify a future quality control. After reviewing the building process, we imagined the packaging, then the transportation, the installation, daily use and the maintenance.

Plans

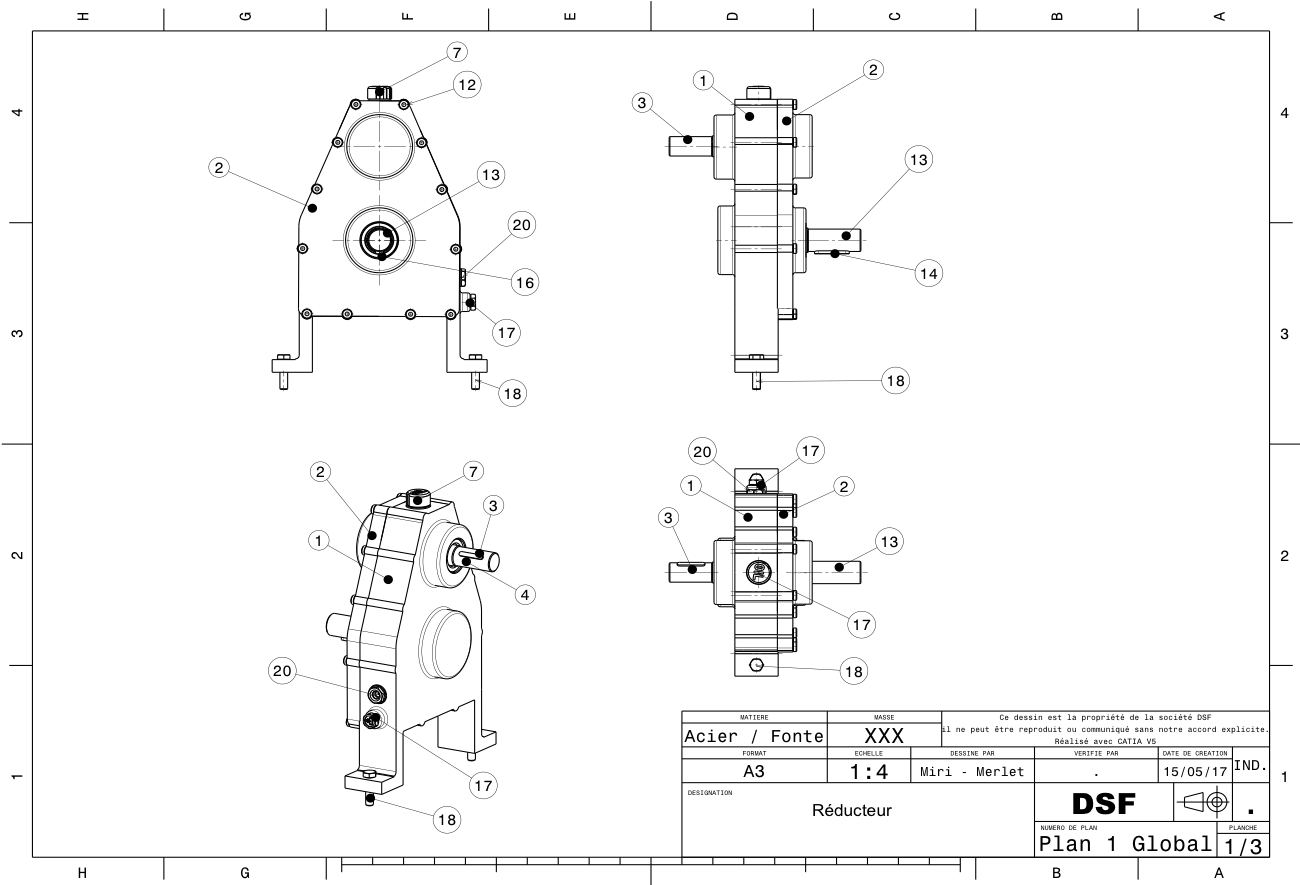

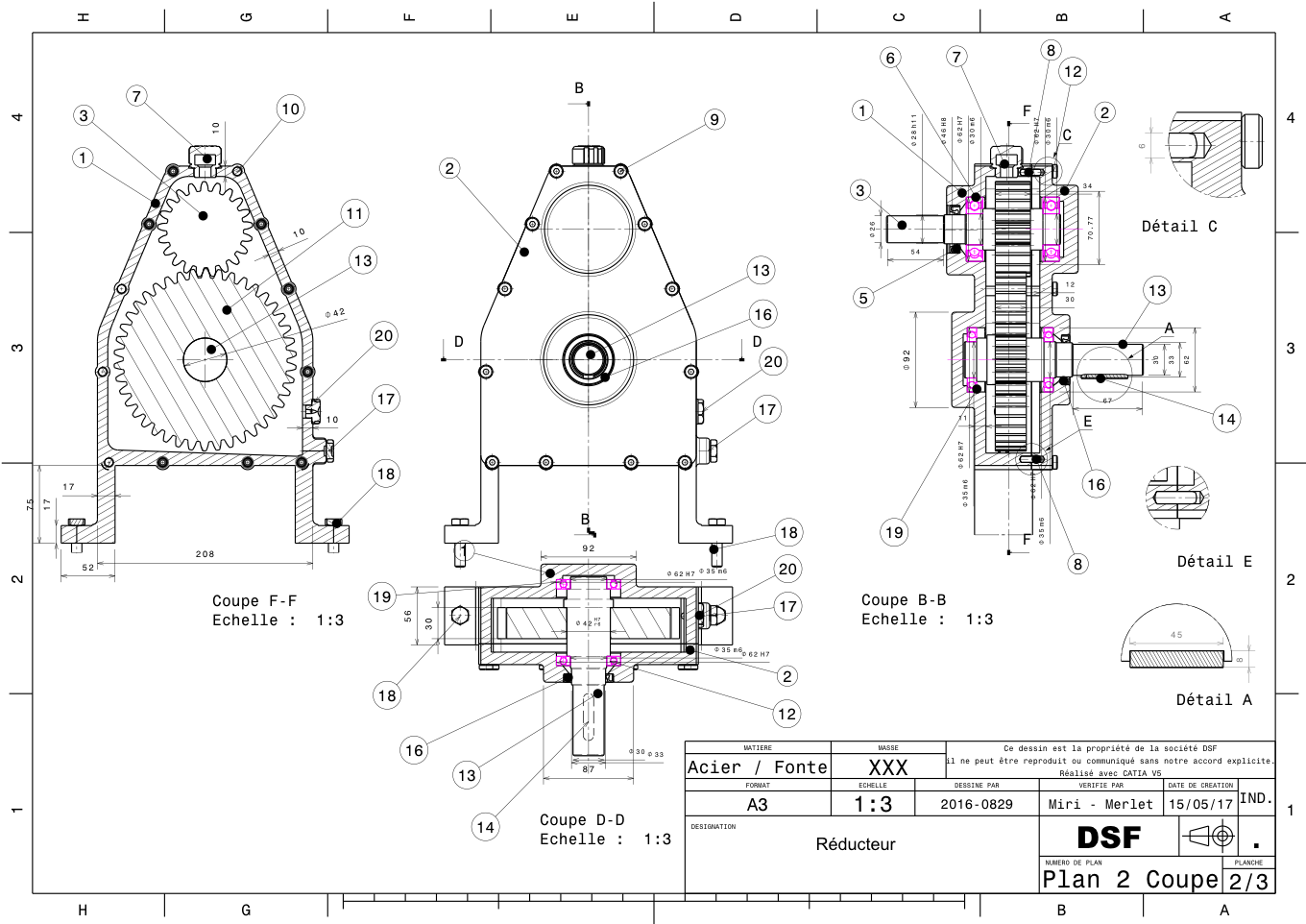

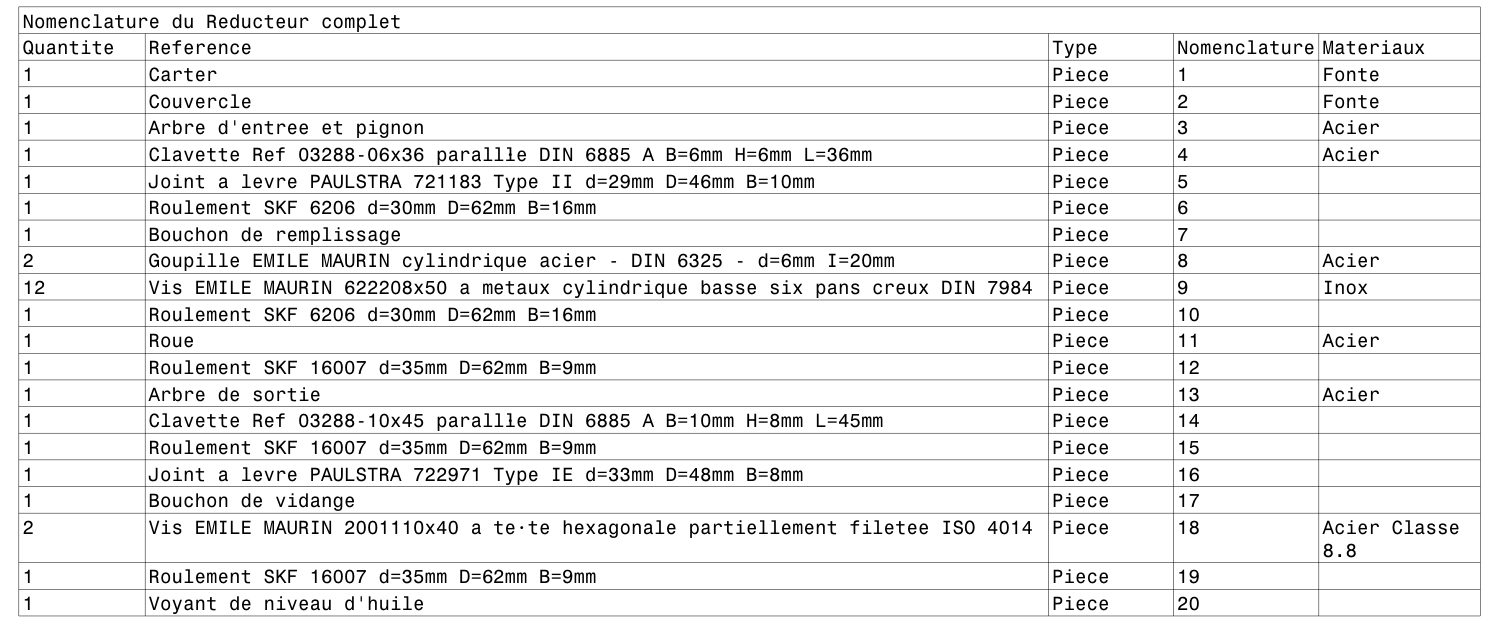

The last step was to create from our simulations the industrial drawings. The first plan is an external view of the system. The second plan presents different cross-sections of the system. And the last one is a nomenclature of it.

Conclusion

This project was really great to discover the conception field. It also helped me to gain experience in CATIA V5 and virtual prototyping.